Screen Printing Tri-Blend Shirts How to Screen Print Tri-blends – Learn How To Screen Print

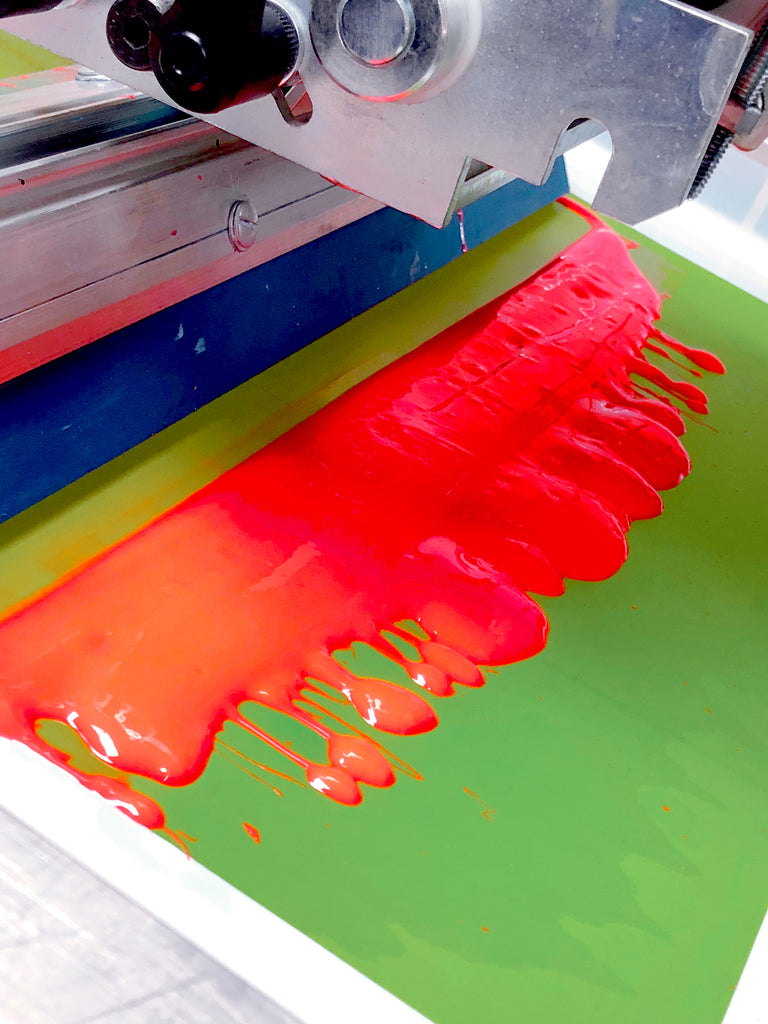

Screen printing tri-blend t-shirts and garments are a great way to increase your profit margin if your printing for customers. But they can also be a quick way to lose money if the prints don't look right and the customer isn't happy since the blank cost for tri-blends is more than cottons tees. So take a couple steps to ensure successful prints on tri-blends and watch your temp, inks and mesh count. When printing Tri-blend garments steps to ensure a successful print are as follows;

Screen Printing vs. Sublimation: Which Process is Better?

Effectively Printing on Tri-Blends - Tips from the Experts

Can You Apply Siser HTV to Tri-Blends? - Siser North America

Rapid Cure® Fluorescent Purple Screen Printing Ink

What You Need To Know About Screen Printing On Tri-Blend Shirts

Rapid Cure® Blue Lagoon Screen Printing Ink (5 Gallon - 640oz.) - Plastisol Ink for Screen Printing Fabric - Low Temperature Curing Plastisol by Screen Print Direct® - Fast Cure

White Plastisol Ink Best Cotton & 50/50 White Screen Print Ink

Rapid Cure® Fluorescent Green Screen Printing Ink (8oz.) - Plastisol Ink for Screen Printing Fabric - Low Temperature Curing Plastisol by Screen Print Direct® - Fast Cure Ink for Silk

Custom Printed Shirts for Bands, Labels & Creatives

Screen printing - Wikipedia

Where to Buy Blank Shirts for Screen Printing

How to Screen Print Wet on Wet Halftones and Color Blends for a Vintage Look